Here.

Yep. On that pad. Right at the end of the curved green line that used to be a rail pit. Back in the days when I was a proud (well, not really) member of the United Steelworkers. I ran a big ol’ Do-All 3-wheel band saw and other various and sundry metalworking tools, including *sigh* a plasma cutter. That’s where I learned to weld steel (badly; I never really got the hang of it) and aluminum (a little better, but only because we spent more time welding aluminum than we did steel). I was better with MIG than I was with TIG. And no, I didn’t do any production welding 🙂

I left there in 1981, though, and a few years later went back to college. In the meantime that factory closed down. I gather Lilly owns the property now; the new construction to the northwest wasn’t there 30 years ago. (Edit to add: Using Google Earth and its historical imagery feature, it appears that the building was torn down sometime between March 25, 1998 and March 26, 1999. Coincidence that I happened to look today? Hmm.)

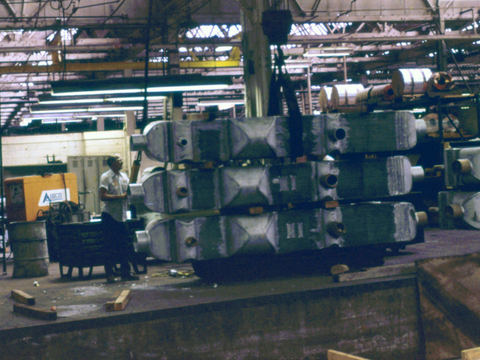

I found this old color slide recently while going through old negatives:

Embiggenator

That’s three cores stacked up (two more over to the right) and our foreman Brownie moving one of them, probably getting ready to manifold them all up. I laid out and cut the headers (the rounded pieces with the pipe sticking out of them) and guys in a welding shop over in the other building put them together and welded them onto the cores. Sometimes the company sold single cores, sometimes it sold several of them manifolded together, and the latter was our shop’s primary task.

This is a fairly good executive summary of what a brazed aluminum plate-fin heat exchanger is all about. Except that when I was in the biz, they were mostly salt-brazed, not vacuum-brazed. We were just getting into vacuum-brazing and frankly that’s where we fucked up. It was useful for small cores but management wanted to be able to build 40-foot-long, 48″x48″ ones to compete with, hmm, Sumitomo I believe, and they could never get the damn things hot enough in the center to braze properly. As my dad (who was the production engineer/manager for all of the Code 9 and Code 11 departments) put it at the time, it was like baking a cake and not getting it done in the center. There was talk about using an inert gas, e.g., argon or helium, to help distribute the heat better, but when I left they had not implemented anything like that. Apparently they’re still in the vacuum brazing business but I don’t see where they’re making big cores like the ones we used to sling around anymore.

After I left SW, I got to work on one of the plants in the field several years later. This one — I think. (Or a similar one in the same general area — I thought I remembered it being east of Fostoria, not west, but I’ve slept since then. Anyway, it’s very similar to the one I remember doing this job at.) If you ever hear me talk about the 25 hour shift I pulled with nothing but dinner and smoke breaks back in the late ’80s, well, the top of that tall skinny building in the middle of the shot — the cold box — is where I watched the sun come up one really frickin’ cold September morning.

I’d spent most of the night with either a saw or a chipping hammer in my hand while we cut out the old core and prepped for installing a new one while waiting for a spare core to be driven up from West Virginia, and then hanging around for the welders to do their job and the inspectors to inspect the welds (and then do more chipping so they could fix problem areas). I should probably also note that we were working in little tunnels that had been dug through the rock wool insulation the cold box was filled with. Very claustrophobic…We had to pull the 25 hour shift because they had a load of liquid nitrogen scheduled for delivery to “kick-start” the air-separation process that morning, and, well, you simply can’t leave cryogenic gases sitting around in the sun…or they start to boil off and you have a pretty big and potentially deadly problem on your hands.

The job paid well but I never wanted to do another one, so it was my first and last foray into field service on the cryo plants.

Anyway…what I really was doing was ruminating on HB’s posting and ended up way off track, didn’t I? 🙂

PS: Bonus points for anyone who knows what that factory was before Stewart-Warner owned it.

One Reply to “I used to work here”

Comments are closed.

Well, OK, fine…it was the old Chevrolet plant 🙂